How To Reprogram 2011 Mustang Radio Youtube

Introduction

This guide will show the user how to accept apart the junction box and clean any corrosion in your 2010-2014 Ford Mustang. If you have corrosion this can crusade electrical bug.

-

-

Pull hood release tab inside the car.

-

-

-

Disconnect the positive side battery cable from the bombardment with an 8mm wrench.

-

Identify the positive side battery cablevision on a non-conductive surface, like a towel.

-

-

-

Pull off the rider side kick-plate console by pulling on the unconnected end with moderate forcefulness.

-

-

-

Remove the six connectors from the junction box. The large connector at the bottom of the junction box will be removed during step six.

-

-

-

Unhook nearby wires from hangers on junction box by using a apartment head screwdriver.

-

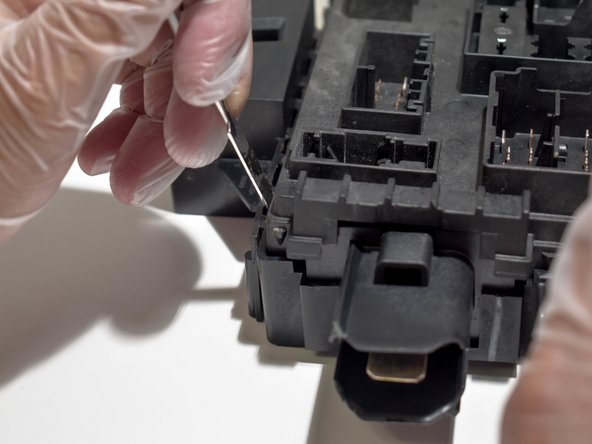

Utilize the screwdriver to push on the hanger tab and then pull the wire connector forward.

-

-

-

Using a x mm socket wrench, remove the mounting nut from lesser of junction box.

-

Slightly lift the junction box and then remove the final large connector on the bottom of the junction box.

-

Elevator the junction box 90 degrees to unhook the junction box from the fender wall and then pull the junction box completely out.

-

-

-

Inspect all connectors for corrosion to indicate where the junction box needs cleaning.

-

-

-

Place the junction box in a clean ventilated area and on a flat surface.

-

Remove the fuse panel cover.

-

-

-

Using the fuse puller located in the fuse embrace, remove all of the small fuses.

-

Remove the larger fuse and relay by manus using moderate forcefulness.

-

-

-

Use a flat head screwdriver or plastic opening tool to detach the modest tabs on the junction box.

-

-

-

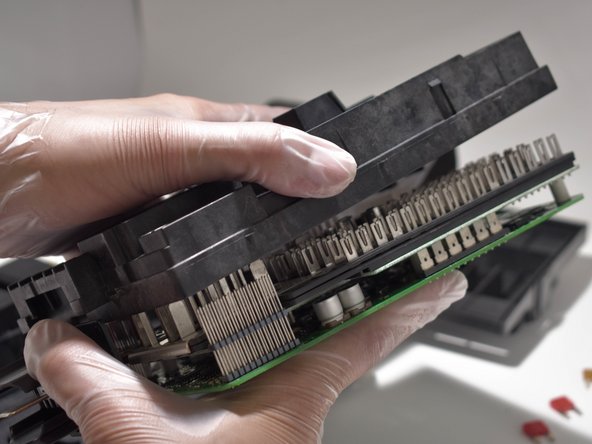

Remove the top plastic cover and the command boards from the bottom cover.

-

-

-

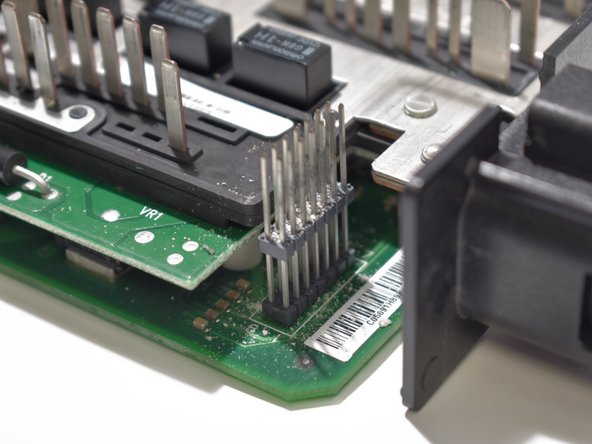

Examine the height junction box encompass for any corrosion or burn spots.

-

-

-

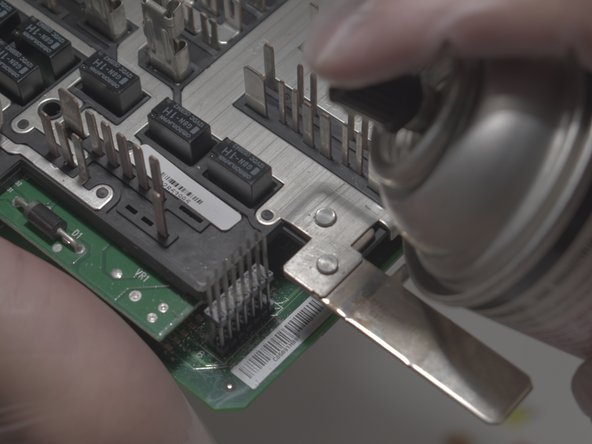

If no burns are plant, spray contact cleaner on corroded areas. If at that place are burns on the control board, the junction box can not be saved.

-

-

-

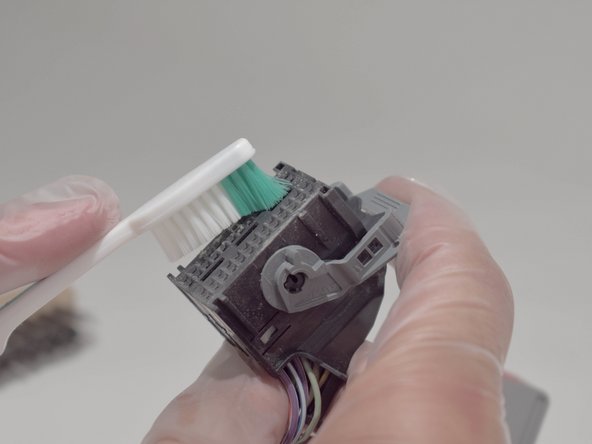

Before the contact cleaner dries, scrub the corroded components on the control board with a tooth brush.

-

Scrub the command lath cover with a wire or soft brush as needed.

-

-

-

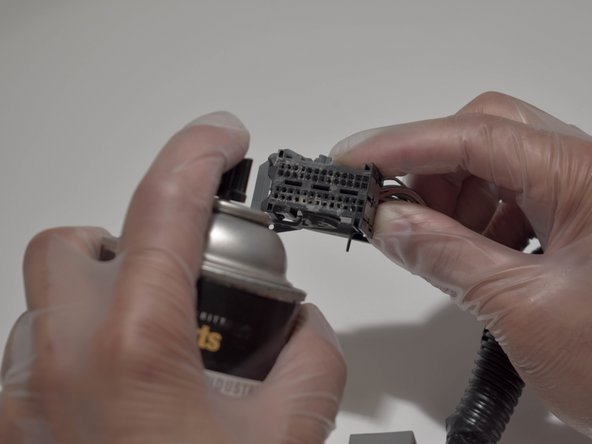

Spray a moderate corporeality of contact cleaner on all corroded wire connectors.

-

Before the contact cleaner dries, use a wire brush or soft brush to make clean off the corrosion.

-

Allow all components to dry for three or more hours.

-

Conclusion

To reassemble your device, follow these instructions in reverse social club.

Embed this guide

Choose a size and copy the code beneath to embed this guide as a small-scale widget on your site / forum.

Preview

Source: https://www.ifixit.com/Guide/How+to+Repair+a+2010+2011+2012+2013+2014+Ford+Mustang+Smart+Junction+Box/124407

Posted by: sellarsvate1986.blogspot.com

0 Response to "How To Reprogram 2011 Mustang Radio Youtube"

Post a Comment